Byuilding Dactul-Manuform: Newbie in DIY edition.

- 725 words

- 4 min

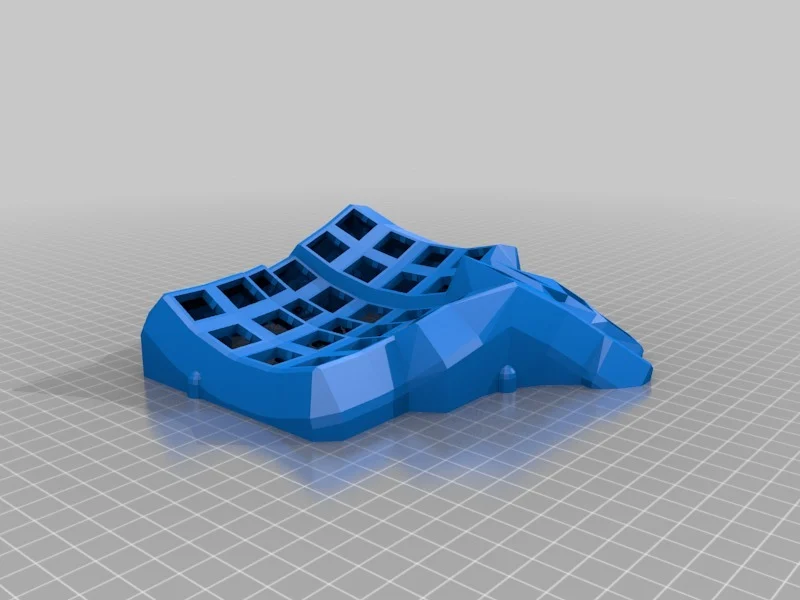

I finally came to the idea that would be nice to have a proper hobby. Also inspired by different kinds of keyboards I found Dactyl-Manuform GitHub project as a great idea for the self-build split keyboard as DIY project.

If you decide to build Dactul-Manuform as well I would recommend you to check github repo and as well this blog helps me a lot: Complete idiot guide for building a dactyl manuform keyboard.

Another important thing - choosing a layout that you want to build. I select the 5x6 layout as closest to the standard keyboard's layout. I assume it will be easier to adapt the layout as it is my first try of a split keyboard.

Purchase list

Following already existing description of Dactul-Manuform repo I've collected a list of materials for this project:

- PLA PF Filament for 3D printer 1,75 mm 1000 g (to print base plate) - ~12,5 USD

- Switches - I'm totally newbie in keyboards nerd stuff, so I've picked up based on general not expensive switches recommendation Gateron G Pro V3 70 pcs. - ~20.8 USD

- Cheapest keykaps on the whole AliExpress ( Blue color probably was a mistake - will see. Anyway I'm planning to change them in the future when will know a little bit more about custom keyboards) - ~4.2 USD

- 2 x Arduino pro micro Micro ATMEGA32U4 Type-C - ~ 9.8 USD

- Female to Female 30sm Jumper Wires - 40 pcs. - ~1.9 USD

- Diodes 1N4148 DO-35 - 100 pcs. - ~1.6 USD

- Rj11 616E connectors ( it will be used for linking 2 arduino with each other) - ~ 1.8 USD

- Brass Insert Nuts M3(OD 4mm) 50 pcs. - ~1.3 USD

- M3 Screw 5mm - ~ 1 USD

- Phone cable to connect 2 part of keyboard - priceless coz it's provide own charm.

3D printing

A friend of mine provide a 3D printer (Ender 3 Pro) to me for printing the base. You are able to find prepared STL's on the repo on github or on thingiverse. On thingverse you are also able to find bottom plates as well.

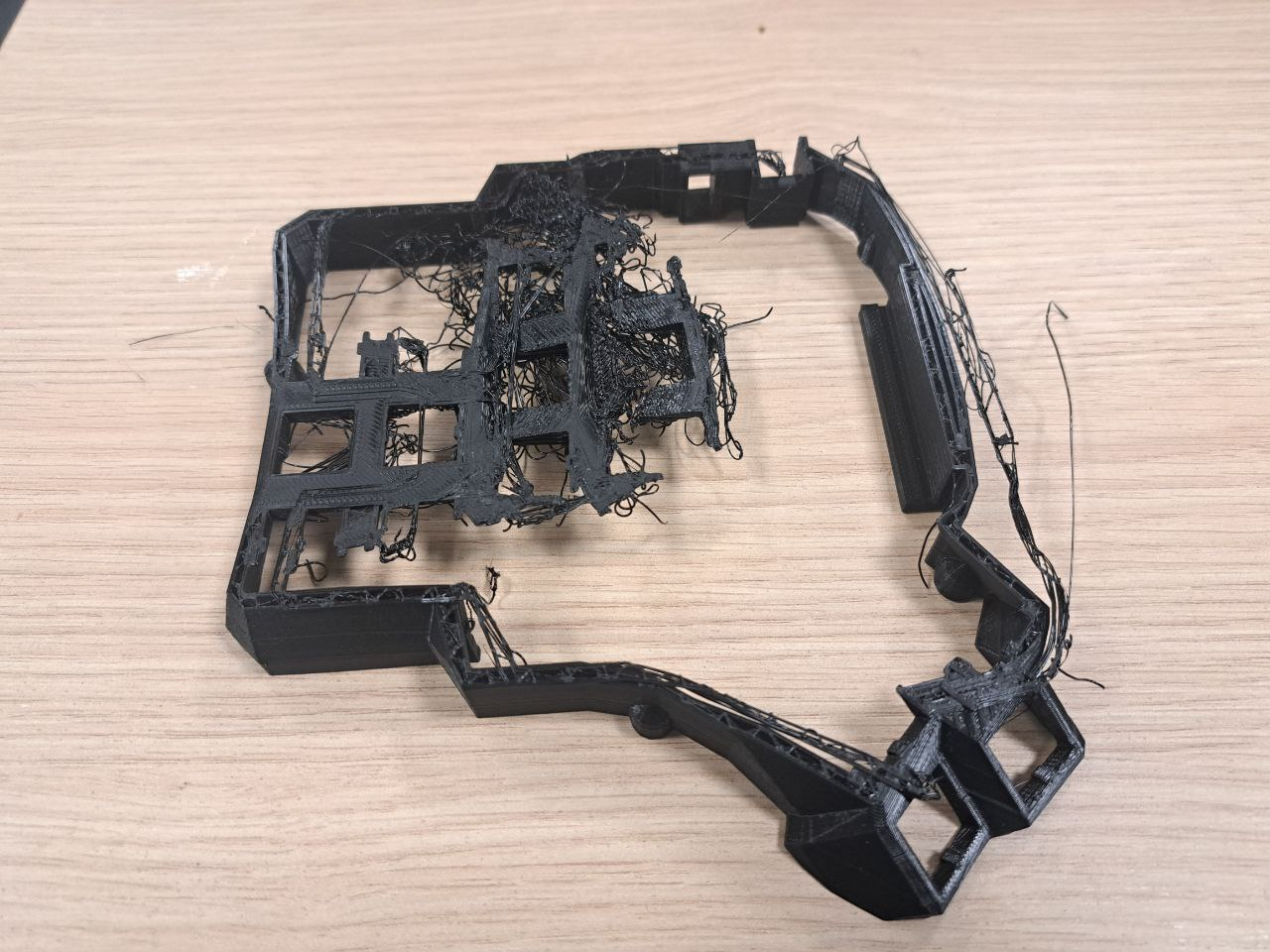

And coz I'm complete newbie in 3D printing first time sure first try was not so successful.

I came up with a question about what's wrong on Reddit and there was a bunch of good advice. But seems the source of the issue was missing a Support Placement during Slicing STL. So basically you can't print a base without printing a Support layers. I first used UltiMaker Cura for slicing. But following Reddit advice I found a pretty full config

from one of the Redditors who have significant experience in printing Dactul. Here the link to the full config.

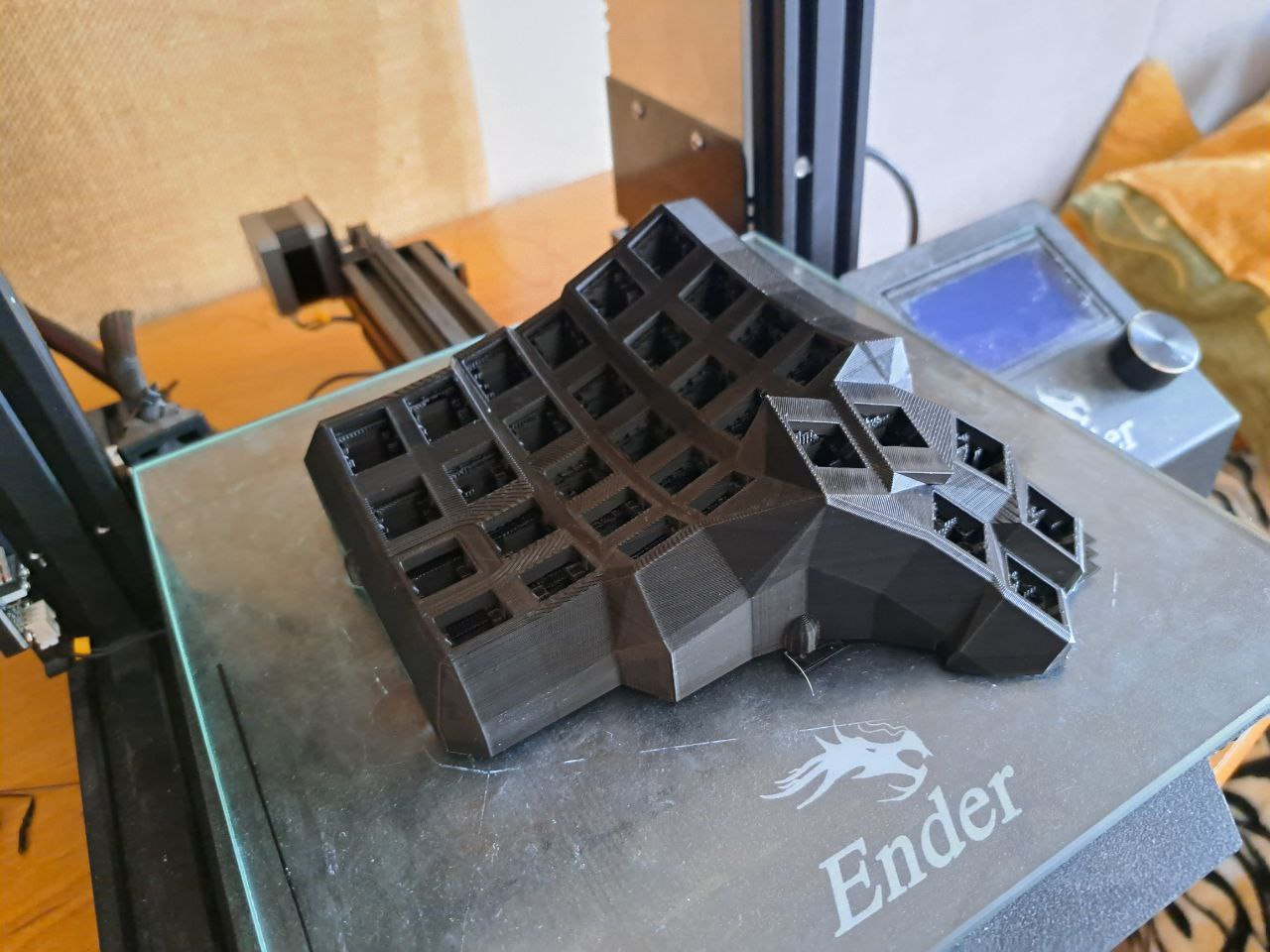

I complete the slice and start printing. You should be patient coz it will take 22h 10min per each base plate.

22 hours later...

Tiny life-hack: to detach the model from printer substrate => move it to refrigerator for 20 minutes. Love physics, under low-temperature detail, will be detached themselves.

And about Support Placement: be ready to spend time to remove it. Based on the config there are a lot of support layers.

Printing result